One definition of “disrupt” is to interrupt by causing a disturbance or problem. But in the business world, to disrupt isn’t a pejorative—it’s a badge of honor, an example of a company that is constantly pushing the envelope to do things better, to dare to be different without worrying about how things have always been done.

FCNews’ fourth annual Industry Disrupters issue features innovative players and thinkers who are changing the game in terms of product enhancements, technological breakthroughs or simply radical new ways of doing business.

Cali Floors

Disrupting through distribution

Cali Floors has proven to be a trusted partner for retailers in the face of hardship. The company has also grown exponentially over the last several years and attributes that growth to the relationships it has with its specialty retail partners.

Cali Floors has proven to be a trusted partner for retailers in the face of hardship. The company has also grown exponentially over the last several years and attributes that growth to the relationships it has with its specialty retail partners.

Part of that relationship is its unique model of product distribution, which includes the specialty retail channel, home centers and even direct to consumer. It’s this disruptive strategy that has helped put Cali on the 2022 Industry Disruptors list.

“Our focus is to create a relationship with the end user early in their journey, and to allow them to move down the funnel and transact where they’re most comfortable,” explained Doug Jackson, Cali president. “Our MSRP and map pricing policy allows that customer to have confidence she’s getting the best price wherever she makes the purchasing decision.”

This strategy has worked for the brand given that it has grown substantially over the last few years—including its recent acquisition by global flooring company Victoria PLC—and continues to expand its specialty retail network.

“This relationship has worked because our retail partners understand they’re not competing with us—it’s all a part of giving that consumer a seamless journey,” Jackson noted. “As that consumer works her way down the funnel, she realizes she’s not going to get fantastic service and installation from other options. When you think of some of the major retailers out there—Ralph Lauren, Levi’s, Apple—it’s about the seamless experience with the brand no matter where they run into that brand and being guaranteed that price is the same no matter what. It’s just a matter of where they have the most comfort transacting.”

Engineered Floors

Fast growing flooring brand keeps pedal to the metal

Engineered Floors is certainly a different company than it was a few years ago. While ascending to become a $1 billion carpet mill within its first 10 years, the Dalton-based company founded by Bob Shaw has since diversified into other areas and undergone a rebranding.

Engineered Floors is certainly a different company than it was a few years ago. While ascending to become a $1 billion carpet mill within its first 10 years, the Dalton-based company founded by Bob Shaw has since diversified into other areas and undergone a rebranding.

Now known as Dream Weaver by Engineered Floors, this retail brand has a presence in SPC/rigid core, laminate and both residential and commercial. “EF is absolutely a leader in the flooring industry and has been a disrupter since our founding in 2009,” said Mike Sanderson, vice president of marketing. “Our PureColor fiber burst onto the scene and truly set the bar for what solution- dyed carpet can be. Over the last 13 years, we have continued to build on our reputation of innovation and quality which has served us well as we broadened our product offering and stepped into other markets. Our commitment to innovation, quality and our people have allowed us to hold the mantle of fastest-growing flooring brand in the world.”

While effectively playing the role of disrupter, Dream Weaver by Engineered Floors hasn’t lost sight of what got it here, according to Sanderson. “The goal of Engineered Floors has always been to make the best carpet possible. We feel we have been doing that over the last 13 years and continue to do so by being an industry leader in innovation, quality and value. We do all of this while maintaining our commitment to northwest Georgia and the surrounding areas. At EF, we believe it is our people that make us great, and it is those people who will continue the tradition of innovation and ensure we make the best carpet possible.”

Mobile Marketing

Helping to create a digital marketing revolution

The flooring industry was slow to embrace the use of digital marketing and online tools as a viable next step in the evolution of the industry. However, spurred by a boom in younger store owners and the COVID-19 pandemic, the need for an impactful digital strategy has become a no-brainer for savvy flooring dealers.

The flooring industry was slow to embrace the use of digital marketing and online tools as a viable next step in the evolution of the industry. However, spurred by a boom in younger store owners and the COVID-19 pandemic, the need for an impactful digital strategy has become a no-brainer for savvy flooring dealers.

With that in mind, there are a select few companies that stand out within the digital marketing space for not only highly customized, results-driven offerings but the foresight to offer tools that help dealers adapt to changing market conditions and support a rapidly evolving industry. Mobile Marketing stands above the rest in its impact on the industry. The company is continually developing and driving new technologies that help its customers grow.

“We offer our clients a customized, comprehensive digital marketing strategy to specifically meet their needs,” explained Carole Cross, founder and CEO of Mobile Marketing. “As more people continue to cut the cable cord, we bring new marketing technologies to our retailers like OTT (over-the-top) advertising, which is advertising done through subscription-based services. Our clients have had early advantages with rapid growth in new channels like geofencing and video advertising. This is in addition to digital advertising such as paid social media, Google ads and more.”

Cross added that Mobile Marketing offers its clients flexible shop-at-home and e-commerce solutions to help them change and expand their ways of doing business—an essential vision in today’s evolving market. “We have developed more fully integrated partnerships with Roomvo, QFloors and Swell. The information gathered by those existing platforms is then utilized to create a more enhanced experience that allows retailers to see the best return on their overall investment.”

AHF Products

From takeover target to blazing the acquisition trail

It was only a few years ago that AHF Products, which owned a trio of brands (Bruce, Hartco and Robbins), was fully divested from then parent company, Armstrong Flooring Industries, and sold to American Industrial Partners, a private equity firm. The move came after Armstrong executives made the decision to specialize solely on resilient flooring—a category that has seen insane growth rates in the high double digits in recent years.

It was only a few years ago that AHF Products, which owned a trio of brands (Bruce, Hartco and Robbins), was fully divested from then parent company, Armstrong Flooring Industries, and sold to American Industrial Partners, a private equity firm. The move came after Armstrong executives made the decision to specialize solely on resilient flooring—a category that has seen insane growth rates in the high double digits in recent years.

Three years and more than a dozen brands later, AHF Products—now owned by Paceline Equity Partners—is in the enviable position of “acquirer” as it seeks to aggressively build on its growing brand and product portfolio. Once a strictly hardwood supplier, AHF has rapidly expanded its offering to include laminate, wood-SPC hybrids and virtually all sub-categories of resilient, including commercial sheet. In a true turnaround story for the ages, AHF has grown, on average, by 20% each of the past three years—including 2020, the year the COVID-19 pandemic hit. That growth rate surpasses that of not only most hardwood suppliers but also the total industry at large. In the past two years alone, the company has launched more than 1,000 new SKUs and placed more than 10,000 displays at retail.

AHF anticipates an acceleration of that growth via its new parent company. “Paceline has ready access to capital to fuel our ideas,” said Brian Carson, president and CEO. “They believe in our growth strategies, and they love the flooring business. They are customer oriented, as we are, and are willing to invest in companies that are innovators in manufacturing, marketing and merchandising.”

These investments are already paying dividends for AHF. The company has expanded capacity at each of its eight plants in 2021. Its solid hardwood plants have invested in new capabilities to maximize throughput and volume, while the company’s engineered facilities now have the capacity, equipment and personnel to produce sliced-faced products—a subcategory previously outsourced.

i4F

Pushing the boundaries of what’s possible

Making FCNews’ annual list of industry disrupters for three straight years is becoming common for companies like i4F, but it never gets to a point where it’s “old hat.” This year, i4F continued its winning ways with the unveiling of what it calls several game-changing innovations.

Making FCNews’ annual list of industry disrupters for three straight years is becoming common for companies like i4F, but it never gets to a point where it’s “old hat.” This year, i4F continued its winning ways with the unveiling of what it calls several game-changing innovations.

First up is True Grout for SPC/rigid core tiles and planks. The innovation allows the creation of a middle grout line that mimics two tiles in one. How it works: The grout is applied at the factory via the addition of a colored wear layer between the décor film and the core. Since grouts are directly milled into this additional wear layer, the risk of grout damage, color deviations, staining and the gathering of mold is eliminated. What’s more, this increased resilience was designed to outperform both v-groove and traditional ceramic grout applications in terms of wear and tear. The design also allows installers to create staggered patterns while cutting total installation time in half.

“Floors and walls enhanced with True Grout technology not only look like real ceramic but improve on the real thing by delivering stronger tiles and planks enabling greater design possibilities in any room,” said John Rietveldt, CEO.

i4F has also expanded its drop-lock technology portfolio via the introduction of a new, patented drop-lock system specifically designed for an easier installation of herringbone panels—an increasingly popular visual among consumers and designers today. According to the company, the new system facilitates the fitting of a herringbone panel’s short side into the long side of an adjacent herringbone panel.

“Due to the more complicated nature of the installation, the placement or repair of herringbone patterns have traditionally almost been exclusively reserved for professionals,” Rietveldt explained. “Our new purpose-built herringbone drop-lock system makes it possible for more end users to do it themselves, by making installation, disassembly and replacements very similar to more conventional flooring installation techniques.”

Inflation

Despite record high prices, momentum for flooring continues

Unless you’ve been hiding under a rock, you know prices on consumer goods have been steadily rising. In fact, the Consumer Price Index rose by 7.9% through February, the fastest pace of annual inflation in 40 years. Rising food and rent costs contributed to the big increase, the Bureau of Labor Statistics said, as did a surge in gas prices that will become more pronounced in the March inflation report.

Unless you’ve been hiding under a rock, you know prices on consumer goods have been steadily rising. In fact, the Consumer Price Index rose by 7.9% through February, the fastest pace of annual inflation in 40 years. Rising food and rent costs contributed to the big increase, the Bureau of Labor Statistics said, as did a surge in gas prices that will become more pronounced in the March inflation report.

Even before Russia invaded Ukraine, oil and gas prices were on the rise as demand for fuel oil and other energy products outstripped tight global supplies. In February, the energy index jumped 3.5% for the largest monthly rise since October. And over the last year, the energy index was up 25.6%. A further impact from the Russia-Ukraine crisis and extended jump in energy prices that has ensued will likely show up in the CPI data in March, given the invasion first began in late February.

Cost increases had been running fast for a year and accelerating for months, posing a problem for the Federal Reserve, which is in charge of achieving price stability.

Fortunately for the flooring industry, inflation has not stalled the two-year rally that retailers have experienced. Nonetheless, inflation is in the back of every flooring retailer’s mind as they worry about the potential psychological effect rising prices—especially at the pump—may have on consumers.

WOFB

A powerful platform for women in flooring

Women of the Flooring Business (WOFB) was launched in 2019 with the mission to support the needs and voices of women in the floor covering industry. Founded by Michelle Winters—then co-owner of Texas-based New Braunfels Flooring—as a social media group with the goal to exalt female store owners while offering a platform to share best practices, WOFB has expanded into an innovative, impactful, grassroots community focused on female empowerment and growth within the flooring industry.

Women of the Flooring Business (WOFB) was launched in 2019 with the mission to support the needs and voices of women in the floor covering industry. Founded by Michelle Winters—then co-owner of Texas-based New Braunfels Flooring—as a social media group with the goal to exalt female store owners while offering a platform to share best practices, WOFB has expanded into an innovative, impactful, grassroots community focused on female empowerment and growth within the flooring industry.

“The flooring business is a bit of a road less traveled for females, where many of us have taught ourselves how to overcome unique obstacles to success in our industry,” Winters told FCNews at the time of the group’s launch. “As a relative newcomer to the business, I quickly discovered that there was no outstanding, easily accessible source for support.”

Today, the group is led by Winters together with industry consultant and longtime FCNews columnist, Lisbeth Calandrino, as well as Rachel Berlin, sales manager at Precision Floors & Décor, Sheboygan, Wis. What started out as just a few hundred members has swelled to more than 2,000 and moved well beyond its social media roots. The group has a dedicated website (womenflooring.com), offers member training and coaching, networking opportunities and educational retreats, not to mention constant one-on-one support.

The group has also partnered with other industry organizations to help spur its forward momentum. “We are continuing our growth by recruiting industry partners to uphold our group’s mission,” Calandrino said. “The WFCA invested in our mission at Surfaces and gave us an hour platform for three days at Surfaces. Their education platform makes them great partners.”

Winters added, “Women of the Flooring Business has accomplished some incredible things with support from across the industry. We are continually developing new programs, including a ‘Fireside Chat’ in April to discuss how to bring young women into the industry and a three-day retreat in Georgia to be held in May to recharge, educate and inspire the women in flooring who attend.”

Stainmaster

End of an era opens window of opportunity

For 35 years, Stainmaster was arguably the most recognized and trusted brand in carpet, renowned for its vivid color, plush texture and, of course, stain-resistant properties.

For 35 years, Stainmaster was arguably the most recognized and trusted brand in carpet, renowned for its vivid color, plush texture and, of course, stain-resistant properties.

And then—in a flash—it was over, as Invista sold the Stainmaster brand to Lowe’s. Suddenly, more than 250 flooring retailers who operated Stainmaster Flooring Centers were left holding the bag, forced to replace their Stainmaster racks and signage with other products.

While the Stainmaster sale was jolting—and ticked off many dealers initially—the vast majority who did business with Stainmaster seized the opportunity to market other fiber systems. In fact, to many retailers, Stainmaster was no longer a power brand. Some mills were even working on a Stainmaster alternative long before the Lowe’s deal was made public.

A case in point is The Dixie Group, which at one time was one of the strongest supporters of the Stainmaster brand. “Over three years ago we began taking steps to protect ourselves in the event this kind of thing happened,” T.M. Nuckols, president of the residential division of TDG, said in reference to the Stainmaster sale. “That is paying off for us now with the impending Invista exit, and we have quickly made very good progress in moving away from Invista fiber.”

In February, Invista informed its carpet fiber customers of its plans to cease production of nylon 6,6 carpet fiber by July this year. When completed, this will mark the end of an era for a fiber business that was started by DuPont over 70 years ago.

Mohawk Industries

Setting new standards in manufacturing, education, sustainability

As the world’s largest flooring manufacturer, Mohawk has disrupted the industry in many ways in this year alone.

As the world’s largest flooring manufacturer, Mohawk has disrupted the industry in many ways in this year alone.

First, it continued to set the standard for those looking to safely host events with the success of its second annual Mohawk Momentum Roadshow. When other organizations shied away from in-person events in January, Mohawk continued to provide personalized product and program experiences directly to consumers—right when they needed them. Over the past two years, Mohawk has put its customers first by bringing the show to them.

Next, never one to back down from a challenge, Mohawk has doubled down on its investment of laminate with the introduction of RevWood Premier with Signature Technology. With the release of Signature Technology, Mohawk has reset the standard for the texture and realism of wood décors. By incorporating 64 layers of design data into each plank, Signature Technology achieves a wood floor that is indistinguishable from natural hardwood, giving retailers the differentiation they need to win in a crowded wood market. In addition, Mohawk has doubled its laminate capacity in North Carolina in order to meet the demand of this highly sought-after product.

Lastly, as America’s largest recycler of plastic bottles, Mohawk is committed to achieving sustainability—taking responsibility for what happens to carpet at the end of its life. Its new, innovative ReCover Backing System is lighter in weight, easier to install and covered by a backing warranty for delamination. ReCover carpet backing reduces consumer warranty claims, increases customer satisfaction and—because it’s 100% recyclable and reusable—offsets landfill disposal costs.

XGS

Powerful suite of services to meet retailer, supplier demands

Long before the industry began feeling the pain of the current supply chain crunch, Xpress Global Systems (XGS) had already begun enhancing its services and logistics capabilities. Whether it’s providing less-than-truckload (LTL) services or access to strategically placed warehousing facilities, XGS helps both its manufacturing partners and retailer customers achieve greater agility and efficiency in managing their flooring shipments and inventory.

Long before the industry began feeling the pain of the current supply chain crunch, Xpress Global Systems (XGS) had already begun enhancing its services and logistics capabilities. Whether it’s providing less-than-truckload (LTL) services or access to strategically placed warehousing facilities, XGS helps both its manufacturing partners and retailer customers achieve greater agility and efficiency in managing their flooring shipments and inventory.

In an age of trucking delays, personnel shortages, delayed delivery times, etc., these capabilities have positioned the company to better deal with the current predicament facing the industry. “Through strategic planning with our internal and external customers, we were able to recognize and accommodate the need for additional services other than transactional LTL,” said Derek Bartley, vice president, XGS. “We built on these offerings with the appropriate technology to become the all-in-one supply chain provider, allowing our partners to focus on their core competencies. Our state-of-the-art transportation management system (TMS) allows us to maximize the utilization of our resources while simplifying our day-to-day operations. In addition to our TMS, we have coupled it with a warehouse management system (WMS) to round out a total digital transformation.”

While Bartley stopped short of describing XGS’s business model as disruptive, one can make the argument that the model on which the company operates has indeed altered the logistics/distribution/warehousing game. At the very least, the approach XGS takes certainly challenges the current industry paradigm. “We have designed an infrastructure in our network to accommodate the entire supply chain where needed—or select what is needed—meaning we can pick up, consolidate, line haul mostly anywhere in the U.S., warehouse, pick/pack, cut to length and deliver locally,” Bartley explained.

The Dixie Group

Outpacing the industry in soft, hard surface

They have a saying at The Dixie Group: “We are obsessed with our customers’ success.” To care that much means truly understanding what customers need and expect—and then striving to exceed those needs and expectations.

They have a saying at The Dixie Group: “We are obsessed with our customers’ success.” To care that much means truly understanding what customers need and expect—and then striving to exceed those needs and expectations.

By all accounts, TDG is executing on that promise. “For the past 18 months, we have significantly outpaced the market in both soft and hard surfaces, which is giving us momentum,” said T.M. Nuckols, president of the residential division. “And I see there are many more customers who are interested in doing business with us today versus a few years ago. I do believe we are the market leader in the high-end residential nylon segment. Our collective nylon offering across Fabrica, Masland and Dixie Home is exceptional. And because we are focused on nylon, the most durable fiber in the industry, our products start beautiful and stay beautiful for a really long time.”

One area that Nuckols said differentiates TDG over the past few years is its aggressive investment in and diversification of its business. “First, we began developing our EnVision nylon strategy over three years ago and this helped us better understand how to work with alternative nylon fibers. Another example is hard surfaces. We have grown our hard surface segment to represent over 15% of our business by Q4 2022. That is excellent progress. To get there, we invested in talent and in product innovation. Also, consider our new decorative programs—1866 by Masland and Décor by Fabrica. High-end decorative is a market space we have underserved for many years.”

Nuckols added that he is confident in TDG’s strategy and direction. “We are going to continue investing in talent and in product innovation to drive growth across all segments of our business. And we will strive to solidify our position as the go-to supplier of high-end residential flooring.”

MSI

A stealthy, purposeful powerhouse

From its humble beginnings more than 47 years ago—and still flying somewhat under the radar—MSI has grown into a powerhouse in the flooring industry. From having no presence in the rigid core market to being one of the category’s top suppliers within only a year attests to its incredible prowess.

From its humble beginnings more than 47 years ago—and still flying somewhat under the radar—MSI has grown into a powerhouse in the flooring industry. From having no presence in the rigid core market to being one of the category’s top suppliers within only a year attests to its incredible prowess.

Today, Raj Shah, president, said it is in the company’s DNA to continuously engineer methodologies in logistics, product innovation, merchandising and marketing to make flooring and ceramic surfaces more affordable to the consumer while supporting the independent retailer—something the company has done successfully over the last several years.

What sets MSI apart—other than it being the 15th largest importer to the U.S., (No. 1-3 are Walmart, Home Depot and Target) and bringing in more than $2 billion in sales annually—is its focus on affordability and accessibility. “I think most people in our industry, historically, have been trying to find ways to charge more for products, and we’re always trying to find ways to charge less without sacrificing anybody’s profitability within the system,” Shah explained.

It’s also about the company’s focus on its retail partners, logistical prowess and ability to control its own destiny when it comes to supply. “We need to have ultimate flexibility within MSI and for the retailer,” Shah noted. “It’s our job to keep the supply chains open for the retailer and product continuing to flow. What we have is our ability to build flexibility and adaptability into our model.”

For example, MSI is bringing LVT and tile from numerous countries outside of China. With supply chains, the company charters its own vessels and built its own fleet of trucks and truck drivers. The company also invested in ROKplank to provide domestic product capabilities in the rigid core segment while also investing in a quartz countertop manufacturing facility.

“We want to be the choice for the retailer,” Shah stated. “We want to make their life simpler.”

NWFA

Leading the way in education, in-person training initiatives

The National Wood Flooring Association (NWFA) is arguably doing more than any other industry association to educate, train and certify floor covering installers and tradesmen to become true wood flooring professionals. Even during the pandemic, when in-person conventions and training events were not happening, NWFA didn’t miss a beat. During in-person training events, the association instituted social distancing practices and took other measures to protect participants.

The National Wood Flooring Association (NWFA) is arguably doing more than any other industry association to educate, train and certify floor covering installers and tradesmen to become true wood flooring professionals. Even during the pandemic, when in-person conventions and training events were not happening, NWFA didn’t miss a beat. During in-person training events, the association instituted social distancing practices and took other measures to protect participants.

“An investment in education is one of the most valuable and tangible investments a business owner can make,” said Brett Miller, vice president of technical standards, training and certification, NWFA.

In those situations where participants can’t make it to NWFA’s headquarters for education and training, NWFA is able to bring the “mountain to Mohammed,” so to speak, by developing on-site programs whereby it works with retailers and contractors on customized programs. “The beauty of investing in customized training is that we are able to come to your business, customize the curriculum and use products and tools your crews are comfortable using,” Miller said. “It makes training seem very personal.”

And let’s not forget about NWFA’s online learning platform, NWFA University (NWFAU). The program complements hands-on training to provide a convenient and affordable training alternative. With NWFAU, participants can complete training at their own pace and on their own terms. NWFAU offers more than 200 courses, with a series of courses leading to “digital badges” that can be shared on various social channels. But here’s the best part: As students participate in more learning opportunities and earn more badges, their name will move up in NWFA’s “Find a Professional” search engine on woodfloors.org—the consumer-facing site created by NWFA.

NWFA’s digital training program continues to grow. The association recently partnered with Footprints Floors, a flooring installation company with 77 owners and 155 franchise locations throughout the United States, to create a learning management system (LMS) for its employees based on content from NWFAU. As a part of the agreement, the NWFA will customize content from NWFAU and provide real-time technical assistance through a newly created Footprints Floors mobile app.

FCEF

Stepping up to solve the installation crisis

The shortage of flooring installers has existed for decades but has grown more dire as installers age and retire, with fewer newcomers ready and trained to take their place.

The shortage of flooring installers has existed for decades but has grown more dire as installers age and retire, with fewer newcomers ready and trained to take their place.

The Floor Covering Education Foundation (FCEF) is one organization that is making a difference. Its mission is to bring awareness to the opportunities in the flooring industry, recruit new talent, aid in the funding of the student’s education and facilitate job placement.

In its short tenure, FCEF is already starting to make an impact. It has partnered with Georgia Northwestern Technical College (GNTC) and collaborated with CFI, CTEF and NWFA to create two 10-week flooring installation basics courses. The curriculum for this course was developed by CFI, CTEF and NWFA. FCEF is also working to get this program accredited, which will allow for more scholarship/grant opportunities for students and help FCEF replicate this program in other schools.

The shortage of installers impacts everyone in the flooring industry and FCEF said it needs the support of everyone in the industry to combat an issue that will require more than one or two years to solve. “We need to bring new people into this industry, and it starts at the local level,” said Jim Aaron, FCEF executive director. “I’m encouraging retailers to get to know your local high school guidance counselor. This issue will not be solved without people’s involvement at the local level.”

Floor & Décor

Continuing to astound the naysayers

The flooring retail industry witnessed its share of disrupters the last 40 years, from home centers and chain stores to mill-operated dealerships and even department stores. Each offered a different business philosophy and aggressive growth strategy. And while all entities experienced varying degrees of success, only the big box model proved sustainable.

The flooring retail industry witnessed its share of disrupters the last 40 years, from home centers and chain stores to mill-operated dealerships and even department stores. Each offered a different business philosophy and aggressive growth strategy. And while all entities experienced varying degrees of success, only the big box model proved sustainable.

That has changed with the expansion and rapid acceleration of Floor & Décor, the Atlanta-based retailer that operates more than 150 locations across 33 states. Truth be told, certain aspects of the Floor & Décor business model are not new, as there are retailers who source directly, operate warehouse-format stores and offer broad flooring choices at competitive prices—all without providing professional installation services. But no one has ever done all this with a massive in-stock assortment of hard surfaces within an average store footprint of 76,000 square feet. (By comparison, the average size flooring department at Home Depot and Lowe’s is roughly 4,000 square feet.)

Floor & Décor’s extensive selection of in-stock products allows customers to get what they need when they need it. The company’s direct sourcing model, which is supported by four large, dedicated distribution centers, enables the company to reduce fractional costs and offer everyday low prices.

“We serve a higher-income customer and they have substantially higher wealth and home equity relative to pre-pandemic levels,” said Tom Taylor, CEO, during a recent earnings call reporting fiscal 2021 and fourth-quarter results.

The strategy is paying big dividends. according to a recent Forbes magazine article, net sales increased a mind-blowing 41.5% over fiscal 2020 and 68% over pre-pandemic 2019. Meanwhile, comparable store sales rose 27.6% over the previous year, which is way above levels of 5.5% in 2020 and 4.9% in 2019. In a hard surface flooring market that averaged 4% growth per year from 2016 to 2021, Floor & Décor did three-times better, with comparable sales up 12.6% on average year-to-year.

Floor & Décor, which is on pace to reach 500 stores or more over the next eight to 10 years, is looking beyond the residential market for future growth. For example, in the spring of 2021, Floor & Décor purchased Spartan Surfaces, a leading end-to-end commercial flooring specifying distribution company.

CFL

Rapidly expanding its global manufacturing footprint

CFL is not a company that likes to toot its own horn but it is sure to make headlines in the coming months. Among the company’s accomplishments of late is its aggressive growth plan. Now employing around 4,500 people, the company invested more than $140 million in the last two years and grew about 50% in 2021 alone.

CFL is not a company that likes to toot its own horn but it is sure to make headlines in the coming months. Among the company’s accomplishments of late is its aggressive growth plan. Now employing around 4,500 people, the company invested more than $140 million in the last two years and grew about 50% in 2021 alone.

One major investment has been the company’s newly constructed and fully operational 252,000-square-foot facility in Calhoun, Ga., which broke ground with plans to build another 250,000 square feet in the near future. In addition to its U.S., Taiwan, Vietnam and Southern Shanghai operations, CFL also started construction on a large facility in Hunan, China, last year.

To further fuel its growth plans, CFL partnered with private equity investors in 2021 in order to prepare for its next growth spurt, all the while keeping a strong overall majority ownership. According to the company, the new investors allow CFL to accelerate its international expansion as well as further its reach within the Chinese market. While the investors do not drive operations, they have the know-how related to international financing, human resources, corporate governance and public relations.

CFL’s product strategy is also fine-tuned and further evidence of its expansive “long game,” which includes growth-only categories: laminate, wood and luxury vinyl.

Surfaces/Market Maker Events

Unapologetically moving the flooring industry forward

The year may be 2022, but concerns surrounding the coronavirus pandemic have far from waned. At a time when some industry events continue to be canceled out of an abundance of caution, some large-scale industry groups continue to lead the charge and move the flooring industry forward.

The year may be 2022, but concerns surrounding the coronavirus pandemic have far from waned. At a time when some industry events continue to be canceled out of an abundance of caution, some large-scale industry groups continue to lead the charge and move the flooring industry forward.

The International Surface Event (TISE), for example, reignited the industry in early February with a full-fledged Surfaces event, again held in Las Vegas. “Surfaces has represented each manufacturer and buyer of the flooring industry for more than two decades and with that comes tremendous responsibility,” said Dana Hicks, TISE show director. “Each January Surfaces brings together our industry to gather in person as a community. When Surfaces is interrupted the industry notices and the rest of the calendar year loses direction and enthusiasm. If you’re not disrupting, you are not staying relevant. We pride ourselves on our business agility.”

Market Maker Events also moved forward with its Flooring Markets—three regional shows in Dallas, Atlanta and Biloxi, Miss.—that drew in thousands of attendees ready to get back to business. “We felt it was critical for the Flooring Markets to move forward as live events to offer attendees the opportunity to see new products in-person,” said Lori Kisner, managing partner, Market Maker Events. “We understand how important it is for buyers to be able to see, feel and touch products in order to make key buying decisions and set their businesses up for success. In the wake of COVID-19, the smaller-scaled structure of our markets was advantageous for us because we were able to move ahead while implementing enhanced safety protocols.”

Shaw Floors

Redefining what it means to service the customer

While some companies talk a good game when it comes to providing top-notch customer service, Shaw boasts a laser-focus approach that is second to none, according to its dealer partners. Whether it’s developing successful stocking programs for their specialty retailer partners (especially the SFN dealers); creating digital education platforms to train retail sales associates and store owners (SFN Live events); leveraging the use of electronic QR codes; or chartering coveted shipping vessels to ensure a ready supply of SPC, Shaw Floors seeks to raise the bar in meeting and/or exceeding customers’ needs.

While some companies talk a good game when it comes to providing top-notch customer service, Shaw boasts a laser-focus approach that is second to none, according to its dealer partners. Whether it’s developing successful stocking programs for their specialty retailer partners (especially the SFN dealers); creating digital education platforms to train retail sales associates and store owners (SFN Live events); leveraging the use of electronic QR codes; or chartering coveted shipping vessels to ensure a ready supply of SPC, Shaw Floors seeks to raise the bar in meeting and/or exceeding customers’ needs.

During the COVID-19 shutdowns, for example, the Shaw Flooring Network (SFN) began connecting with members in an entirely new way. The first SFN Open was in January 2021; the most recent was the SFN Open “Live from the Dallas Market,” a one-of-a-kind, two-day event that was put together for members of the network. The virtual show allowed SFN members to experience the Dallas market from the comfort of their own showrooms, expanding Shaw’s reach to include retail sales associates who seldom get the benefit of training at an in-person convention. Beyond the requisite product training, the event also gave participants an opportunity to hear a broad range of insightful and inspiring messages from renowned leaders in the world of pro sports, business, publishing and beyond.

Further on the technology front, Shaw is using QR codes more often and in a variety of ways. Specifically, the company is leveraging the technology to more effectively reach its customers, installers and end users by featuring the technology on POP materials, signage, packaging and other marketing materials. These user-friendly QR codes, which can be loaded on web-enabled devices such as smartphones, allow consumers to explore product information online while shopping in-store. This provides a seamless shopping experience for the customer while providing a quick reference for RSAs during a sale.

But all these bells and whistles are for naught if retailers can’t get their hands on product, particularly SPC. To that end, Shaw has chartered several shipping vessels to help facilitate the movement from factories overseas to retail showrooms in America. It’s one of the ways Shaw is working to alleviate some of the supply chain issues currently plaguing the industry at large.

Unilin Technologies

Helping suppliers make better products

Unilin Technologies put the spotlight on its ongoing R&D efforts at Surfaces 2022 in Las Vegas earlier this year, marking its return U.S. trade shows after many years. Here, the company utilized the opportunity to effectively demonstrate how its expertise in innovative, patented processes and technologies allows its partners to make floors that perform better and look more realistic.

Unilin Technologies put the spotlight on its ongoing R&D efforts at Surfaces 2022 in Las Vegas earlier this year, marking its return U.S. trade shows after many years. Here, the company utilized the opportunity to effectively demonstrate how its expertise in innovative, patented processes and technologies allows its partners to make floors that perform better and look more realistic.

While Unilin Technologies’ expertise spans across several disciplines—including glueless locking systems, rigid core materials, digital printing and improved bevel technologies—two disruptive technologies in particular garnered a lot of attention at the show: XPC and Unicoat. The former entails a newly developed core material that is completely dimensionally stable, providing an upgraded and PVC-free alternative to common SPC products. According to Unilin Technologies, the new core material has all the advantages of standard rigid core products, including a click system and being waterproof, plus the additional benefit of extreme dimensional stability. This improved strength means the core will not expand when heated up nor shrink when cooled down—a problem seen in some SPC flooring products.

“XPC is a real game changer for the industry and has the potential to be the next big thing in resilient flooring,” said Floris Koopmans, sales director, IP.

Unicoat, by comparison, is a water-repellent coating that prevents liquids from penetrating into the joints of a floor, particularly laminates, thus protecting both the floor and substrate from water damage. How it works: The coating, which is applied to the edges of the floorboard at the factory, forms a tight seal, protecting against water leaks, spills or accidents by actively repelling the water from the edges and keeping the water on the surface level until it can be cleaned.

“With these two disruptive technologies, we want to elevate the resilient and laminate industry to the next level,” Koopmans said.

Inhaus

Expanding its capabilities by leaps, bounds

Inhaus is no stranger to FCNews’ list of industry disrupters. The company looked to raise the stakes in the rigid core game with Sono Eclipse as well as its groundbreaking innovations in laminate flooring design and performance. More recently, the company developed a new manufacturing method that literally shaves weeks off the sample development process. Now Inhaus is at it again by leveraging its environmentally conscious approach to manufacturing in the development of more sustainable hard surface flooring. At the same time, Inhaus is applying its technical know-how to create some of the most realistic visuals available.

Inhaus is no stranger to FCNews’ list of industry disrupters. The company looked to raise the stakes in the rigid core game with Sono Eclipse as well as its groundbreaking innovations in laminate flooring design and performance. More recently, the company developed a new manufacturing method that literally shaves weeks off the sample development process. Now Inhaus is at it again by leveraging its environmentally conscious approach to manufacturing in the development of more sustainable hard surface flooring. At the same time, Inhaus is applying its technical know-how to create some of the most realistic visuals available.

According to Inhaus CEO, Derek Welbourn, the company has taken a different approach to plastic products than the rest of the industry. In short, placing a higher emphasis on recycling materials that go into producing the cores in its products as opposed to utilizing virgin materials.

“There’s really two components,” Welbourn said. “It’s actually having recycled content in your product and actually having that recycled content be economical. If it’s economical, that means it’s sustainable and desirable both from a personal perspective, but also from a company/financial perspective. That just allows you to do more and more of it.”

Inhaus’ environmentally conscious mindset is at the core of its manufacturing mindset. It also represents a competitive advantage for the Germany-based supplier, Welbourn said. In fact, Inhaus earned a coveted Best of Surfaces 2022 for its sustainable approach to manufacturing.

What’s more, Inhaus invests in world-class equipment, like digital printers, and truly takes the time to perfect the skill associated with it in order to create the best product possible. “Anybody can buy a guitar, but not everyone can be Eddie van Halen,” Welbourn said. “We’ve found that to be so true. There is a huge art to making that happen, both in terms of efficiency and realism. We’ve had world-class digital print equipment for over a decade now and it has taken us that long, quite frankly, to get to how great our products look.”

Mannington

Still winning with design prowess, product inn

You know you’re onto something when you’re a repeat winner in the annual Best of Surfaces awards co-sponsored by Informa. We’re talking about Mannington Mills—long regarded for its design and manufacturing prowess—which has earned a spot on FCNews’ 2022 Industry Disrupters list.

You know you’re onto something when you’re a repeat winner in the annual Best of Surfaces awards co-sponsored by Informa. We’re talking about Mannington Mills—long regarded for its design and manufacturing prowess—which has earned a spot on FCNews’ 2022 Industry Disrupters list.

In 2020, Mannington turned heads at Surfaces with its Adura Apex Legacy Hexagon and Baltic Hexagon LVT patterns, which took home the gold in the Style and Design category. The eye-catching product features cutting-edge technology that allows for the creation of stunning marble visuals that can be installed in a fraction of the time as real tile—all without spacers.

Fast forward to Surfaces 2022, the company earned top honors in a completely different category (Technology) with its next-generation bevel innovation—CraftedEdge, which makes LVT look more like real hardwood. The technology creates a chiseled, hand-crafted bevel found on today’s most luxurious floors. It is featured on Regency and Calico in Adura Max and Adura Rigid.

“We were extremely honored and pleased to win the award,” said David Sheehan, vice president, residential hard surface, Mannington Mills. “For us, it’s validation for a kind of strategy that we are getting back to in residential hard surface. Historically, we have been known for style and design and always been an innovative company. We’re trying to get back to the innovative side with a nuance of meaningful innovation that matters to the consumer.”

Zack Zehner, president of Mannington Residential, attributes the company’s award-winning streak to its hard-earned reputation for style and design leadership. “The biggest differentiator for us from a styling standpoint is we’re doing it with this crew here,” he said, acknowledging its on-staff design team. “We’re not picking stuff off a shelf. This design team is building visuals based on what they’re seeing in home fashion trends. We continue to elevate our styling, and this team continues to challenge themselves.”

Broadlume

Building systems to help retailers stay on their ‘A’ game

Broadlume has gradually increased its growing suite of end-user solutions in recent years. Now the company is looking to change the game with its unique retail platform officially unveiled at the FloorCon convention last fall.

Broadlume has gradually increased its growing suite of end-user solutions in recent years. Now the company is looking to change the game with its unique retail platform officially unveiled at the FloorCon convention last fall.

Instead of having to log into multiple programs to perform basic functions, see data, etc., Broadlume saw the opportunity to integrate these various programs into one seamless platform. “When we got into this space and when we were really focusing on how we can help independent flooring retailers, the biggest piece of feedback that we constantly get is we’re looking for things to be simplified,” said Jeffrey Bieber, vice president of marketing, Broadlume.

Broadlume not only simplified key processes, but it went two or three steps above, building a specific “tech stack” by acquiring companies such as Creating Your Space, FloorForce, Retail Lead Management and RollMaster in order to successfully cater to all of a retailer’s needs. These include tools retailers can use to: more effectively track leads; help consumers better visualize products; and better manage inventory management—all on a singular, easy-to-use platform.

Aside from the seamlessly integrated aspect of the platform, its performance and security sets it apart from what’s currently available. “If you look in the industry, security has to be No. 1, especially when you’re talking about an ERP system, financial and accounting platforms,” Bieber explained. “You need to have the best security and you need to be protected. That’s something that we’re constantly focused on—where are the gaps? Where are the vulnerabilities?”

In order to accomplish this, Broadlume strives to acquire industry professionals with years of experience from some of the largest and most respected technology companies in the industry. “The people that we’re bringing in to help build this for the industry is also one of the unique things about our company,” Bieber said. “We are constantly looking at bringing in top talent to build these tools and systems.”

Välinge

Innovation is embedded in its DNA

Ever since introducing a click system for laminate floors in 1996, Välinge has been disrupting the industry with one innovation after another. In recent years, Välinge has evolved from a technology and licensing company to a licensor that now manufactures some ground-breaking technologies.

Ever since introducing a click system for laminate floors in 1996, Välinge has been disrupting the industry with one innovation after another. In recent years, Välinge has evolved from a technology and licensing company to a licensor that now manufactures some ground-breaking technologies.

Some recent examples:

- Newly launched Topshelf technology is a type of protective wear layer foil that provides wear resistance without increasing the thickness of the wear layer or opening for thinner wear layer to be used. It replaces conventional wear layer without changing anything in the existing LVT/SPC or PVC-free resilient flooring production process.

- Liteback technology is one of its brightest stars on the resilient side. Liteback saves up to 20% of material, resulting in a lighter product that is lowering transportation costs while creating better sound properties.

- A technology advance from Välinge includes a new format and locking system that allows faster installation of herringbone patterns—an increasingly popular look in homes and commercial applications. To simplify installation for installers, planks in each box are marked accordingly (i.e., “A” and “B” panels) and the herringbone strips feature 5G locking technology.

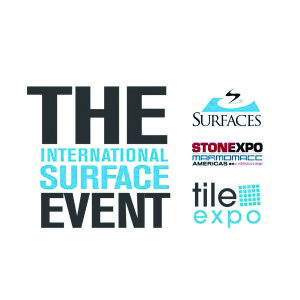

- Hygienius coating, a technology Välinge bills as an “invisible” room cleaner. How it works: A hardwood or resilient floor with Hygienius integrated in its lacquer layer enables a natural photocatalytic process to take place when exposed to daylight or indoor light. This allows harmful emissions and unpleasant odors to be broken down as well as degradation of bacteria, fungi and even virus on the surface.

Hallmark

A novel spin on traditional hardwood coloring techniques

Imagine if you could employ a custom colorization process that made obsolete the use of traditional, factory-applied stains or dyes commonly utilized at hardwood flooring production plants today. Now further imagine this specialized process enabled the color or hue of the face of the wood to penetrate through the entire thickness of the hardwood wear layer, right down to the edge of the core.

Imagine if you could employ a custom colorization process that made obsolete the use of traditional, factory-applied stains or dyes commonly utilized at hardwood flooring production plants today. Now further imagine this specialized process enabled the color or hue of the face of the wood to penetrate through the entire thickness of the hardwood wear layer, right down to the edge of the core.

One company, Hallmark Floors, has figured out a way to do both in its True Hardwood collection. Utilizing a revolutionary, “all-through” color process, the raw wood material is treated with salt and minerals to achieve a 100% natural color—no dyes or stains whatsoever. Rather, this innovative technique replicates the naturally occurring “bog-wood process,” a phenomenon that occurs when hardwood logs lie submerged deep in lakes and rivers where they are deprived of oxygen and sunlight—in many cases for hundreds of years. The remarkable difference is Hallmark has managed to emulate Mother Nature’s methods to create these stunning, naturally occurring visuals in a fraction of that time.

The end result is an array of deep, saturated colors and weathered patinas that span the spectrum from pale grays and browns to dark, golden browns and grays and charcoal hues with a platinum sheen. Or, if the customer is looking for a completely black finish—a look that’s still popular among high-end applications today—that’s possible as well.

The benefits of Hallmark’s True Hardwood collection—which earned the company a Good Design Award in 2020—go beyond just its visual attributes. The product’s deep coloring process enables multiple opportunities to sand the floor over time without the need to reapply a stain on site. In addition, the all-through color process makes it easier to repair or touch-up the floor in the event of a gouge or other household accidents.

Products in Hallmark’s True Hardwood Collection feature the company’s Nu Oil hardwood matte finish, which provides a protective layer despite its low sheen. The product’s engineered wood structure also provides greater dimensional stability, giving homeowners and end users greater peace of mind.

Republic Floor

Turning today’s logistics model on its head

Republic Floor is changing the way suppliers bring product to market. Instead of partnering with regional distributors to take on their product lines, Republic is actually acquiring distributors in certain markets. This is not the conventional way of bringing product to market in such a mature industry like flooring, but Republic has never embraced “doing things the way things have always been done.” Along with those distributor acquisitions come valuable assets such as warehouse space, distribution centers, trucks and, in some cases, drivers. In areas where it can’t purchase distributors, Republic is building distribution centers and contracting with major commercial truck builders to buy vehicles.

Republic Floor is changing the way suppliers bring product to market. Instead of partnering with regional distributors to take on their product lines, Republic is actually acquiring distributors in certain markets. This is not the conventional way of bringing product to market in such a mature industry like flooring, but Republic has never embraced “doing things the way things have always been done.” Along with those distributor acquisitions come valuable assets such as warehouse space, distribution centers, trucks and, in some cases, drivers. In areas where it can’t purchase distributors, Republic is building distribution centers and contracting with major commercial truck builders to buy vehicles.

“The market in general is very challenging today; you cannot get any orders for almost any materials—it doesn’t matter where,” Rotem Eylor, Republic Floor CEO, told FCNews. “If you try to order a tractor trailer today, you won’t get any date or commitment from the manufacturers. We were able to secure supply a couple years ago, ahead of all this.”

Republic is also looking to buck the trend of having to wait for months on end for deliveries/shipments to come through the ports by contracting with shipping companies and port operators to guarantee shipping lanes, cranes, etc. Yes, it’s a much more expensive proposition, but it allows Republic to import products from its manufacturer partners around the world while keeping disruptions to a minimum.

“Two years ago, we made the direct commitment with the ocean line companies for ‘X’ amount of containers,” Eylor recalled. “Whether we use them or not, we’re paying for them. We didn’t lock the price, but we locked the commitment for space on the ship.”

For Republic Floor, everything ties in together—the expansion of its trucking fleet; the increase in the number of warehouses and distribution centers; the arrangements made with vendor partners and shipping companies; and, of course, the rapid growth of its customer base. One of the primary drivers behind its move to bolster its strengths in all these areas, according to Eylor, was the elevation of its status from specialty supplier to “core vendor” with the National Floorcovering Alliance. The high level of service required by NFA dealers, he noted, required a commensurate increase in the company’s service, delivery and logistics capabilities.