Those of us who fondly recall that catchy slogan from the BASF Specialty Chemical ads—“We don’t make a lot of the products you buy; we make a lot of the products you buy better”—can certainly appreciate the approach that Unilin Technologies takes in partnering with major flooring manufacturers to raise the ante on product performance.

“We give companies the knowledge and necessary licenses to produce exciting innovative products,” said Floris Koopmans, sales director, IP, at Unilin Technologies. “The Technologies division of Unilin doesn’t sell the product themselves; rather, we open up the know-how and expertise for others to make it.”

That market-driven focus will be on full display at Surfaces 2022, where Unilin Technologies plans to showcase and demonstrate its technological prowess spanning several areas (glueless locking systems, rigid core materials, grout technologies, antimicrobial surface treatments and digital printing, to name a few) covering trendy flooring categories such as SPC, laminate and rigid core hybrids.

The company occupied roughly 1,000 square feet within the highly trafficked Mohawk space, where it conducted interactive demos for visitors, customers and potential licensees. “It will be good to meet with our direct clients as well as our indirect clients—the buyers, the importers and distributors in the U.S.,” Koopmans told Floor Covering News. “We’ve had a lot of new technology launches over the past 20 years, some of them really groundbreaking. Our popular locking systems are proof of that. Over the years, especially the past few years, we kept inventing and putting more effort into research and development than ever before.”

The fruits of those R&D efforts will be front and center on the Surfaces show floor, where the company will be presenting an astounding array of technologies, both existing and emerging. Following is an overview of what attendees can expect to see from Unilin Technologies:

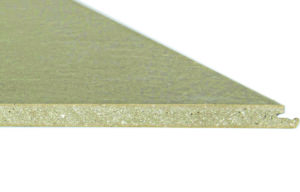

New core materials

XPC, or “eXtreme dimensional stable polymer core,” is a new flooring core material that aims to take SPC to the next level. “It’s an extremely stable polymer composite,” Koopmans explained. “It has all the advantages of an SPC—the look and feel of SPC and a click locking system like an SPC—but it is extremely dimensionally stable. Even if the sun is shining directly on the floor, it will not shrink or expand with temperature. It offers the performance of ceramic tile but has the thickness of an SPC panel. It’s also waterproof and PVC-free, which helps because the price of PVC is going up tremendously. We believe XPC is a real game-changer for the industry.”

Another PVC-free core innovation from Unilin Technologies is P-SPC, a circular flooring alternative made from PET that provides a more environmentally friendly construction while still offering the high performance for which SPC is known. “PET-SPC, or P-SPC as we call it, offers the possibility to be made from recycled materials and is by itself perfectly recyclable, offering immense opportunities for the circular challenges in our industries,” Koopmans said. “With an increased focus on sustainability, environmentally friendly components and recyclability P-SPC will contribute to a more durable resilient flooring market.”

A third new core technology Unilin Technologies is launching at TISE is Comfort Core, a silent and soft floor. “It features a soft foam cushion underneath the top vinyl layer that improves the sound properties, ergonomics and walkability of SPC,” Koopmans said. “You can almost compare it to walking on carpet, because the sound is much better than walking on traditional SPC. It’s not only more sustainable and recyclable, but it’s also an upgrade in performance.”

Click innovations

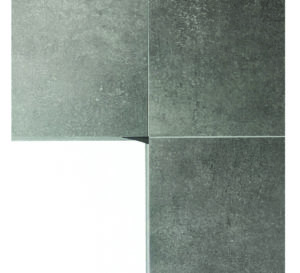

Unilin Technologies takes the wraps off SquareClic, a new innovation that enables more secure installation of square tiles. Heretofore, square floorboards often made checkerboard pattern installations challenging due to extremely tight tolerances and little wiggle room for error. According to Koopmans, SquareClic solves this issue.

“It’s something that a lot of people have been wanting for a very long time in the industry,” he said. What’s more, it’s user friendly. “Using a small installation tool, this is a perfect way to lay square tiles in a perfect checkerboard pattern.”

Beyond SquareClic, Unilin Technologies will also showcase some of its other signature lock- ing technologies. That includes both its popular Uniclic angle-angle click system as well as Unidrop, a “fold-down” locking platform. “The big advantage of Unidrop is you can install it much like a regular fold-down but with a light tap of a hammer,” Koopmans explained. “We’ve also developed Unizip, a locking system specifically designed for herringbone patterns, which have become more popular.”

Grout systems

For those installers and DIY consumers who prefer the look and feel of real grout on resilient flooring planks and tiles without the fuss and mess associated with applying grout to more complex ceramic tile installations, Unilin Technologies said it has the solution: Unigrout. Here, the planks utilize U-shaped beveled edges that look like a grouted groove without the mess. “It’s basically the closest you can get to the design of real grout, but you just click it and go,” Koopmans explained. “The grout lines are built into the manufacturing process when the planks are milled.”

For those who are more comfortable in applying real grout on site, Unilin Technologies has an answer for that as well. The company partnered with a manufacturer of an epoxy-based material that can be applied to the bevels of an SPC product for a truly waterproof installation. Koopmans explained how it works: “You click all the tiles together and then you grout them. You put real grout—which is epoxy based—and then you get the perfect ceramic imitation that’s 100% waterproof. It’s a click system so you don’t need the spacers. And it’s easy to clean off the surface with a sponge before it dries. And the best part is cure time is two hours versus a few days with real tile.”

Protecting laminate

Most people are familiar with the durability and visual appeal laminate flooring offers. However, as a product whose MDF or HDF core is still largely wood based, laminate has limitations when it comes to the ability to stand up to damage from prolonged water exposure. With Unicoat, a technology designed to drastically reduce water incursion into the seams and edges of the laminate planks, damage from spills or flooding can be eliminated, according to Unilin Technologies.

How it works: An advanced coating material prevents water from penetrating between the joints, thereby stopping any water from getting underneath the floor where it could cause mold. In addition, Unicoat forms a shielding layer on the edges of the floorboards, which prevents swelling of the core material and discoloration on the edges of wood top layers.

Mohawk has utilized this technology in the form of HydroSeal and WetProtect on its popular RevWood products. Now, according to Koopmans, that exact same technology will be available on a licensing basis to the industry at large. “We are trying to make laminate a real waterproof option to put it on par with SPC and WPC,” he explained. “Everyone knows that the original laminate floors had swelling and discoloration on the edges when they came into contact with water. This coating addresses that by preventing water from seeping into the joints. This will definitely elevate laminate to the next level.”

Lastly, Unilin Technologies is promoting ActiveGuard—antimicrobial technology for the floor that works by eliminating the opportunity for harmful bacteria to grow on the surface of the floor. Koopmans said it works by preventing enzyme production that fuels bacterial growth. “The coating has a triple purpose that disrupts, disables and destroys bacteria.”

What’s next

Not one to rest on its laurels, Unilin Technologies vowed to continue exploring new opportunities to improve the performance, function and visual attributes of today’s popular hard surface flooring options. The company said it will work closely with digital printing companies, producers of magnetic flooring and other innovators to keep raising the proverbial bar.

“Digital printing is the future of the flooring industry,” Koopmans explained. “Our partners are bringing products to market that are exceptionally good quality. Likewise, we try to focus on what the industry needs and create innovations that matter. For us, the possibilities are endless.”