By Lindsay Gonzalez

Las Vegas—Resilient flooring manufacturers pulled out all the stops at the International Surface Event (TISE) held here last month. While the entire resilient category was represented at TISE, it is clear rigid, WPC—and now MGO—have become the category’s headliners.

Resilient manufacturers introduced a plethora of innovations in hopes of creating diversification within these hypercompetitive subcategories. The goal, industry executives say, is to launch high-quality products that will give dealers and distributors something unique to sell.

“Resilient in the market is still far from slowing down,” said Piet Dossche, CEO of USFloors and executive vice president of Shaw Hard Surface. “LVT is still the category that will move the needle in 2020. There are several new core technologies that are coming to market. MGO core technology is being shown by many manufacturers. We have also exhausted the plank format. I believe the next looks will be in stone and ceramic as well as wall applications.”

From newer visuals and cores to increased texture and longer lengths, the TISE show floor was the place to find resilient flooring solutions for everyone. Following are some of the resilient trends seen throughout the show.

Colors, textures

Resilient visuals often follow trends seen in natural wood, stone and ceramic. As such, many of the new LVT, rigid and WPC offerings displayed on the TISE show floor were cleaner wood visuals with little to no knots; stone and ceramic looks that mimicked marble and porcelain designs; and overall lighter colors. While darker, rustic visuals still made an appearance, manufacturers said design trends are leaning toward the warmer, cleaner looks.

Mohawk was one of the manufacturers touting unique visuals in its 2020 lineup. “From a décor standpoint, we’re starting to bring forward a mix of cleaner looks with low or no knot counts to SolidTech Plus,” Ed Sanchez, vice president product management, Mohawk Industries, explained. “You have updated decors and painted bevels, but the ‘Plus’ is really for performance.”

SolidTech Plus is manufactured with two layers of fiberglass that is impregnated with SPC. According to Sanchez, this method creates a product that is infinitely stable. “As a result, we offer a no-gap guarantee, no-acclimation guarantee and we don’t pro-rate,” he added. “We do a 20-mil wear layer, and our chemical engineers worked to create a proprietary lacquer coating that makes SolidTech Plus scratch and stain proof.”

Within the Mohawk family of brands, Pergo Extreme is focused on providing a visual for every customer. “When you think about the Pergo offerings, we have 60 SKUs available,” Sanchez said. “Depending on who you are and who your customers are, we have a visual for you.”

Available in both wood and stone Pergo provides consumers with the visuals they want along with an easier installation, 100% dent proof, waterproof, kid proof and pet proof as well as a lifetime warranty.

Raskin Industries is looking to take its visuals to the next level with its new digitally printed rigid product called RI Digital. “It is extremely realistic,” said Michael Raskin, president and founder. “We have design flexibility with digital printing. We introduced wood planks and stones; however, the stone and ceramic looks are a real opportunity because we’re using similar printing technology to real ceramic.”

According to Raskin, the DPI is twice that of LVT. What’s more, instead of applying a wear layer, RI Digital features an AC6 and anti-stain coating. This, he said, allows for the product to retain more of its texture, creating a product that closely mimics real stone and wood to the touch.

Forbo Floors is playing with both visuals and textures with its Flotex product, which combines the practicality of a resilient flooring with the slip-resistant and acoustic properties generally associated with textiles. “Flotex is exploding for us,” said Tim Donahue, residential national sales manager. “It allows us, residentially, to truly solve concerns homeowners have when talking about cleanability and aspects textile flooring doesn’t provide.”

With Flotex, the consumer still gets a 6.6 nylon, which provides sound absorption and non-slip properties. However, she also gets waterproof floor that is easier to clean than regular carpet, according to Donahue.

Not to be outdone, Wellmade is also adding to its planks’ textures and styles with painted bevels and embossed in register. “We started with a composite core with the HDPC,” explained Steve Wagner, director of marketing. “The core is 100% waterproof and dimensionally stable. It’s good in rooms with sliding glass doors. New this year we have painted bevels, which the market demanded. In addition, we’re moving into tile looks.”

Making its Surfaces debut in the rigid arena is Karastan LuxeCraft. This new product from Karastan features wood décor inspired by original wood creations discovered in nature. “Our design team worked with our global design partners to find products that are really unique and have a story,” Mohawk’s Sanchez said. “We wanted to have this mixture of the best designs with the best design technologies. Our design team was able to take wood looks that you would never see in a large format and design these unique visuals.”

In addition to LuxeCraft’s visuals, the company worked with its partners at Unilin to leverage embossing technology. “We worked with our coating providers to put on a low-gloss coating,” Sanchez explained. “Real wood isn’t shiny and if you look at this stuff it isn’t, either. The way we coat and the way we integrate our coating with our embossing you don’t have that glitter other products have.”

Longer lengths

Over the years, LVT, rigid and WPC have continued to mimic the larger plank sizes found in traditional and engineered hard- wood. This year was no exception with two of the largest plank sizes in WPC making their debut on the TISE show floor.

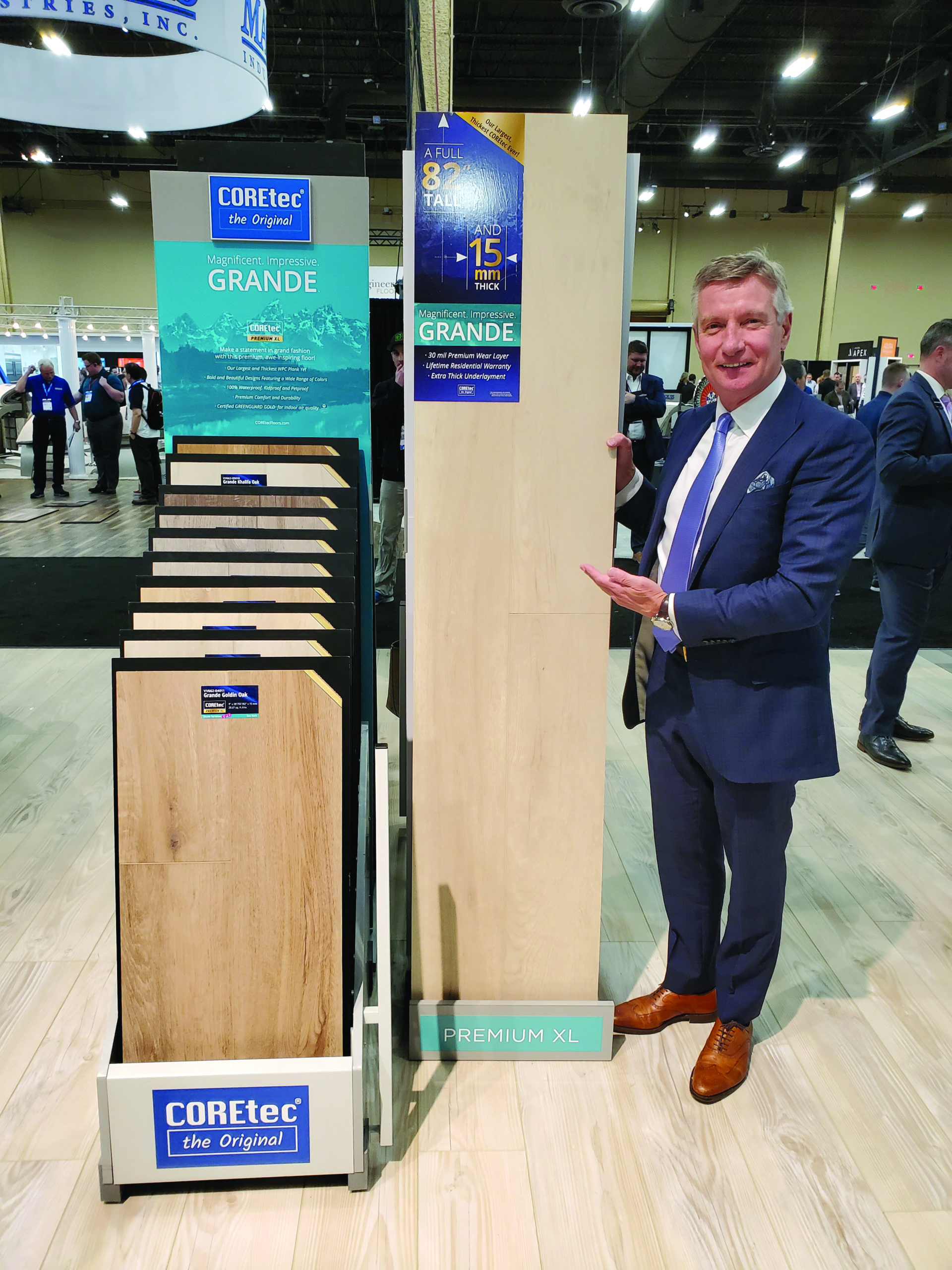

COREtec’s new Grande product is featured on the company’s Premium XL platform. At 82 inches long x 9 inches wide and 15mm thick, COREtec Grande is one of the largest WPC products in the industry. “Seven years ago at TISE we launched COREtec,” said Natalie Cady, COREtec and hardwood category manager, Shaw Industries. “What we want to do every year is keep that innovation going.”

Prior to launching this behemoth, COREtec took its time to get the designs right. As John Crews, design manager, Shaw Industries, explained, “The design story is really about authenticity and the connection to nature. The visuals we selected are lighter, more expressive. They really have a lot of character to them. It’s 9 x 82 inches so we really wanted to make sure the designs we chose made sense on the longer plank. We paid attention to a lower gloss level. We felt that design was in the details with this product.”

The second product to stand tall is Trucor Prime XXL from The Dixie Group’s Trucor brand. This WPC construction available in a 10 x 84-inch format and is 10mm thick. “Trying to be innovative and a little different, we have to go wider and longer,” said Jamann Stepp, vice president of hard surface, The Dixie Group. “In the real wood category what’s selling today are the higher-end looks and longer looks.”

Trucor Prime XXL features customer-proprietary films that belong to the manufacturer. Trucor is launching this long plank in 18 SKUs, in a display that can hold up to 36 SKUs. Additional visuals will be forth- coming, according to Stepp.

Installation made easier

Manufacturers are doing their part to helps installers lay down the floors quicker and more efficiently. Many are mimicking the looks and constructions of natural products that are sometimes harder to install; others are replicating looks in different format to create design and installation options.

Karndean Designflooring, known for its designs, has taken one of its glue-down options and transformed it into a rigid format. “Similar to what we did with Van Gogh last year, we are offering Knight Tile in a glue-down and rigid format,” said Katherine Caringola, communications man- ager. “We’re offering homeowners the colors they want in the solutions the need.”

In the commercial realm, American Biltrite has introduced Ultra Ceramic Contract—the next generation of its original Ultra Ceramic geared toward residential applications. “We have built Ultra Ceramic Contract with a 20-mil wear layer, which allows us to go commercial,” said Mark Tickle, marketing director. “We’ve come out with the same visuals as Ultra Ceramic, but the edge treatment is completely unique. This allows Ultra Ceramic Contract to go into places such as hospitality, offices, libraries. It installs and grouts in one day, and the cost is lower than a real ceramic installation.”

New constructions

When USFloors first launched COREtec in 2013, the brand-new WPC product took the industry by storm. Over the years more manufacturers have entered the WPC arena, some even pushing beyond the original waterproof flooring to create products with alternative cores such as SPC/rigid. Innovation in these resilient subsegments continues with the launch of new cores— such as MGO and ESPC—as well as new constructions.

SLCC, for instance, has an SPC product with an ABA construction featuring two layers of vinyl with an SPC core in the middle. “When you walk around [the show] everyone is going to try to sell SPC on price,” said Chris Dillon, vice president of sales and marketing. “We’re doing the opposite—we’re trying to make it better. We’re going to more of the medium to high end with our SPC. It has two layers of vinyl and we’re creating 10 new SKUs this year.”

Within the past year or so, MGO cores have penetrated the rigid market. One line taking advantage of this new core is Tenacity, a 100% PVC-free product. Tenacity is an MGO-based product with a green story thanks in part to its recycled underlayment. The engineered stone product features Tritec for scratch, stain and dent resistance as well as Net Plus Underlays, which is made from recycled plastic bottles.

“Tenacity fills up a market segment that was needed in the industry,” said Thomas Baert, president, CFL Flooring. “SPC is doing great, but again, what is the next step? We are heavily into engineered stone products with a green story. A few distributors have already launched Tenacity and had great success at a few regional shows. When you bring something new to market you never know what is going to happen, but when your customers come back and tell you they’ve sold 50 displays in one day you realize you’re on the right track.”

Happy Feet also introduced a new product that has a new construction and core. Its Black Label collection is what the company calls an ESPC—or engineered SPC. “We put a vinyl top on a rigid core with vinyl below,” Casey Johnson, owner, explained. “Plus, we put a 28-mil wear layer on it, registered emboss and painted bevel.”

Black Label comes in bigger sizes as well with 9 x 60-inch planks in seven wood visuals and 9 x 36-inch formats for the tile.

(For more, see the Feb. 2/10, 2020 print edition.)