By Ken Ryan The luxury vinyl flooring category has enjoyed multiple years of double-digit growth, starting with LVT, transitioning to LVT/WPC and finally with SPC entering the fray. SPC, or solid polymer core, is a rigid core product poised to lead this resilient subsegment in 2019.

Indeed, many flooring observers view SPC as an improved version of traditional vinyl flooring—faster and easier to manufacture than WPC and, therefore, less expensive to produce.

As the new kid on the block, here are five things dealers should know about SPC products.

What’s in a name?

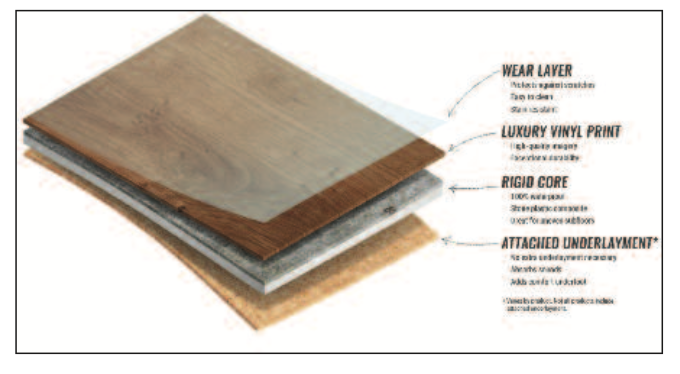

According to the Multilayer Flooring Association (MFA), “SPC” refers to the class of rigid vinyl flooring products with a solid polymer core. That solid, waterproof core, experts say, won’t ripple, swell or peel no matter how much liquid it is subjected to.

This core is ultra-dense with no foaming agents such as those found in traditional WPC flooring. It provides slightly less resiliency underfoot but is said to make the flooring extremely durable.

SPC flooring is virtually indistinguishable from stone or wood flooring due to the printed vinyl layer, which continues to refine the product’s style and design and brings it closer to real wood looks and textures.

The dense, highly mineral-filled extruded core of SPC provides superior indentation resistance and is best suitable for high-traffic and commercial applications. Not all rigid core floors will include underlayment, but it is a popular option as an attached underlayment will deliver extra cushion underfoot and absorb sound.

Low barrier to entry

There are at least two reasons why rigid core has seen a surge in popularity among vendors, with new companies entering the market seemingly every month: a) it is the fastest growing subsegment of the fastest growing category; and b) the cost of entry is relatively minimal.

Chinese laminate manufacturers with idle equipment stemming from the Lumber Liquidators’ debacle three years ago jumped into the rigid core field in a big way. For $250,000, suppliers can purchase or lease a smaller single extruder to get started in the SPC business. In addition, short equipment lead times spanning between 90 and 120 days allows for quick ramp up.

The future is bright

Composite waterproof flooring led by SPC will be the high double-digit growth engine in hard surfaces over the next five years, experts predict. Composite/SPC tiles as an alternative to ceramic tiles is the next big growth opportunity for a slew of reasons: These SPC tiles are lighter and warmer than ceramic; they don’tbreak and are cheaper/easier to install (click); no grout is needed; they are easier to remove and are more comfortable to walk/stand on with its attached cork backing.

According to Piet Dossche, CEO of USFloors, there is also the environmental element to consider. “Natural resources have become scarcer and more expensive. Therefore, composite/fake wood flooring is in. Younger generations take eco-friendliness to the next level. They want Mother Earth left alone.”

Primed for growth

In 2018, sales of WPC products outpaced SPC at the retail level, according to many dealers. This year, however, SPC is expected to make that leap to the top spot in this subcategory. “I expect [SPC] to have the largest growth in 2019,” said Eric Mondragon, hard surface buyer, R.C. Willey Home Furnishings, Salt Lake City. “Rigid core now fills the entry-level price point that WPC had to vacate due to the tariff price increases.”

Commercial ready

Although SPC is suitable for any environment where you need a durable, waterproof floor, it is ideal for settings such as commercial kitchens and bathrooms as well as grocery stores and other venues where spills occur. Unlike traditional vinyl that is flexible, manufacturers designed rigid core to be unbending. As such, it is virtually indestructible.

Dossche on WPC: The best is yet to come

The growth of SPC won’t come at the expense of WPC, according to Piet Dossche, founder and CEO of USFloors and the COREtec brand. Dossche said he sees WPC and SPC succeeding “hand in hand” in the market, with WPC used more for residential applications and SPC for commercial jobs.

Following are five reasons why Dossche said WPC will remain viable.

- Proven technology. WPC is a proven technology already in the market now for the last six years—manufactured under the auspices and quality control from the top U.S. flooring mills and by the LVT experts in China. “The complexity and significant capital commitment to manufacture WPC has kept the manufacturing landscape clean of all those fly-by-night, opportunistic start-ups that entered the SPC market and are not committed to quality and long-term sustainability of the product,” Dossche said.

- Profitable for all. By now, billions of square feet have been sold without any quality problems and claims, according to Dossche, generating billions of dollars in revenue and profit for the entire supply chain. “Pricing discipline on WPC is in place and profitability secured for both the manufacturers and retailers. We have been able to stop the race to the bottom with WPC [unlike SPC] and avoided commoditization and margin destruction.”

- Best looks, luxurious constructions. Dossche said the construction—with an LVT top layer on top of the extruded core—enables the best embossing and surface finishing, making for the most authentic looks. “With WPC you can clearly mimic a wood floor to its utmost and create the thickness of a 1⁄2-inch plank without the challenges of weight in shipping and handling.”

- Ultimate comfort for households. With its foamed-up core and built-in air pockets, WPC provides exceptional comfort, warmth and sound dampening—ideal for active families with kids playing and crawling on the floor. Perfectly suitable for residential applications, WPC brings the hand and comfort of a 60-ounce saxony to the LVT segment with SPC constructed for performance and more commercial applications, comparable to a 26-ounce. level loop commercial carpet.

- ‘The Original.’ Dossche said WPC is the innovative and original rigid core product that has revolutionized the entire flooring industry and became the pioneer and trendsetter in the market. “It will continue to move the bar in originality and creativity while securing the long-term viability of the category. The leadership position it holds in the rigid LVT category makes it the guardian of this new flooring segment and, as the disruptor it is known as, it will relentlessly drive the industry forward and continuously challenge the status quo.